-

gusluk

- Новичок

- Сообщения: 23

- Зарегистрирован: 02 ноя 2012, 05:51

- Репутация: 0

- Контактная информация:

-

gusluk

- Новичок

- Сообщения: 23

- Зарегистрирован: 02 ноя 2012, 05:51

- Репутация: 0

- Контактная информация:

-

Nick

- Мастер

- Сообщения: 22776

- Зарегистрирован: 23 ноя 2009, 16:45

- Репутация: 1735

- Заслуга: Developer

- Откуда: Gatchina, Saint-Petersburg distr., Russia

- Контактная информация:

Re: Mach: Radius to end of arc differs from radius to start

Сообщение

Nick » 13 ноя 2012, 18:06

Посмотри в настройках, пишут, что:

Mach3’s General Configuration page has check-boxes for plane and absolute/incremental ‘IJ’ mode.

-

gusluk

- Новичок

- Сообщения: 23

- Зарегистрирован: 02 ноя 2012, 05:51

- Репутация: 0

- Контактная информация:

-

Nick

- Мастер

- Сообщения: 22776

- Зарегистрирован: 23 ноя 2009, 16:45

- Репутация: 1735

- Заслуга: Developer

- Откуда: Gatchina, Saint-Petersburg distr., Russia

- Контактная информация:

Re: Mach: Radius to end of arc differs from radius to start

Сообщение

Nick » 14 ноя 2012, 11:34

IJ должны быть в incremental mode.

gusluk писал(а):А этот код работает нормально.

работает нормально потому, что окружности в режиме R делаются.

-

Nick

- Мастер

- Сообщения: 22776

- Зарегистрирован: 23 ноя 2009, 16:45

- Репутация: 1735

- Заслуга: Developer

- Откуда: Gatchina, Saint-Petersburg distr., Russia

-

Контактная информация:

Re: Mach: Radius to end of arc differs from radius to start

Сообщение

Nick » 14 ноя 2012, 14:42

gusluk писал(а): но в конце пишет footer.

В смысле footer?

gusluk писал(а):А если поставить Distance mode в absolute, a IJ в mode inc,

Именно так и должно быть. Просто некоторые программы умеют выставлять эти параметры через Gкод, это G90 и G91.1 соответственно.

Hi, I’m getting the “Radius to end of arc differs from radius to start” error in Mach3. It does not prevent me from machining but randomly adds toolpath offsets and has left me with a pile of broken carbide and a pile of wasted stock.

It is only since trying to manually re-run certain Ops within mach that I stumbled upon the error at all.

Other wise it simply presents as the tool randomly offsetting in the x/y and ruining parts.

I have used rhinocam extensively in the past and never had this problem, but since moving to fusion it has plagued me. I am assuming that the problem is with the post processor. I am using the standard Mach3Mill post processor included with f360, I have latest stable version of mach3 and I’m using an ESS motion controller with the latest drivers/plugin.

I can rule out mechanical and electronic error as I have replaced everything other than the mill’s castings chasing this problem before catching a glimpse of this ‘radius differing’ problem.

I have attached a copy of an NC file I have been trying to machine today. It fails consistently by offsetting toolpaths from where they are supposed to be, almost as if the workpiece origin is shifting, as can be seen in the attached image. After this error has occurred I can enter g0 x0 y0 into the MDI and it will not return to the original x0 y0 coordinates (also pictured). It is not being caused from lost steps or slipping couplers.

Any help resolving this would be appreciated

- Index

- Recent Topics

- Search

- www.linuxcnc.org

- GCode and Part Programs

- CAD CAM

- Radius to end of arc differs from radius to start

04 Mar 2017 22:47 #89010

by Jake

I am having a bit of a challenge with this piece of code. It is a boring cycle with a 1/4″ EM I have read through some of the other threads that have had a similar issue. My CAM Fusion360 was set on 4 decimal places, I did stretch it out to 5 and it is still giving me the same error. Anybody familiar enough with Fusion360 cam to know how to work through this?

Thanks!

(BORE1) N260 M9 N265 M1 N270 T2 M6 N275 T5 N280 S8000 M3 N285 G54 N290 M7 N300 G0 X-1.875 Y-1.475 N305 G43 Z0.6 H2 N310 G0 Z0.08 N315 G1 Z0.025 F30. N320 G18 G3 X-1.9 Z0. I-0.025 K0. N325 G1 X-1.9125 N330 G17 G3 X-1.9375 Y-1.5 I0. J-0.025 <------Its blowing up here. N335 X-1.5625 Z-0.0197 I0.1875 J0. N340 X-1.9375 Z-0.0394 I-0.1875 J0. N345 X-1.5625 Z-0.0591 I0.1875 J0. N350 X-1.9375 Z-0.0787 I-0.1875 J0. N355 X-1.5625 Z-0.0984 I0.1875 J0. N360 X-1.9375 Z-0.1181 I-0.1875 J0. N365 X-1.5625 Z-0.1378 I0.1875 J0. N370 X-1.9375 Z-0.1575 I-0.1875 J0. N375 X-1.5625 Z-0.1772 I0.1875 J0. N380 X-1.9375 Z-0.1969 I-0.1875 J0. N385 X-1.5625 Z-0.2165 I0.1875 J0. N390 X-1.9375 Z-0.2362 I-0.1875 J0. N395 X-1.5625 Z-0.2559 I0.1875 J0. N400 X-1.9375 Z-0.2756 I-0.1875 J0. N405 X-1.5625 Z-0.2953 I0.1875 J0. N410 X-1.9375 Z-0.315 I-0.1875 J0. N415 X-1.5625 Z-0.3346 I0.1875 J0. N420 X-1.9375 Z-0.3543 I-0.1875 J0. N425 X-1.7353 Y-1.6869 Z-0.3647 I0.1875 J0. N430 X-1.5648 Y-1.4707 Z-0.375 I-0.0147 J0.1869 N435 X-1.9352 Y-1.5293 I-0.1852 J-0.0293 N440 X-1.5648 Y-1.4707 I0.1852 J0.0293 N445 X-1.5934 Y-1.4499 I-0.0247 J-0.0039 N450 G1 X-1.6058 Y-1.4518 N455 X-1.6096 Y-1.4525 Z-0.3747 N460 X-1.6134 Y-1.4531 Z-0.3738 N465 X-1.617 Y-1.4536 Z-0.3723 N470 X-1.6203 Y-1.4541 Z-0.3702 N475 X-1.6232 Y-1.4546 Z-0.3677 N480 X-1.6257 Y-1.455 Z-0.3647 N485 X-1.6278 Y-1.4553 Z-0.3613 N490 X-1.6292 Y-1.4556 Z-0.3577 N495 X-1.6301 Y-1.4557 Z-0.3539 N500 X-1.6304 Y-1.4558 Z-0.35 N505 G0 Z0.6 N515 M5 N520 G53 Z0.

Please Log in or Create an account to join the conversation.

04 Mar 2017 23:54 #89012

by tommylight

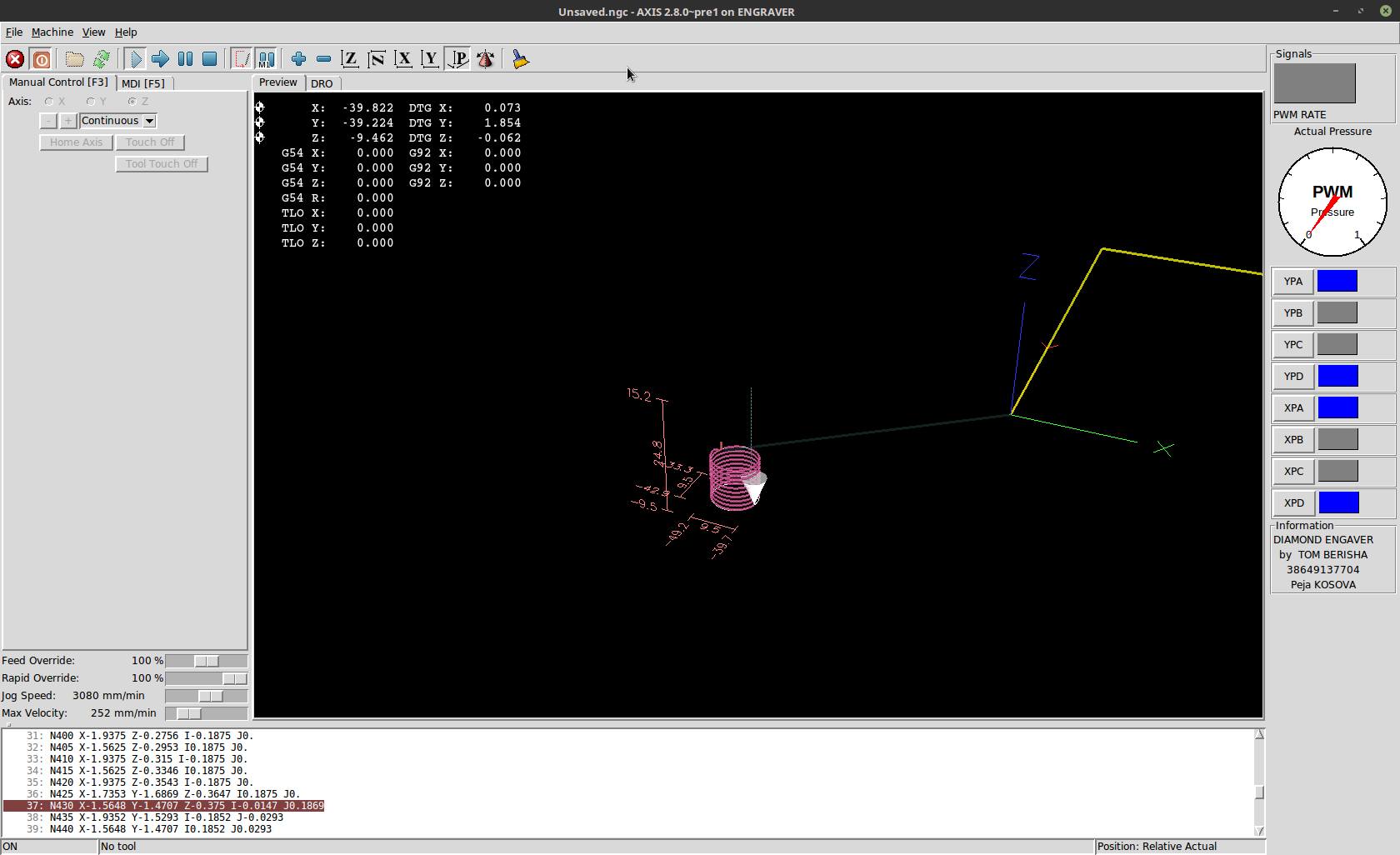

It is all good here, see attached.

The only thing (besides some weird tool changes and Z0.???? ), check the tool to be used and the radius you are trying to cut, tool has to be smaller diameter than the radius to be cut.

Please Log in or Create an account to join the conversation.

05 Mar 2017 01:14 #89014

by Jake

Thanks Tommy!

Its a 1/4 endmill, 9.5mm = .0.374 + 0.25 should put me right there. A guy on the Fusion forum said move my tolerance to 0.0001 and it made it happy, Ill go try it in a little bit.

The “Z0.???”

Are you talking about line N315? Yeah I could add some top clearance in, I left it since the 25/64″ hole is already drilled so I can rapid right to the top of the piece.

Please Log in or Create an account to join the conversation.

05 Mar 2017 02:50 #89017

by Jake

I had my tool table screwed up. When I was setting my Z offsets on the tools I didnt have the correct axis selected it looks like. As the T2 and T5 offsets were in the Y. It runs on the SIM. We will see if it will run tommorrow. thanks again for the help.

Please Log in or Create an account to join the conversation.

26 Mar 2017 17:13 #90302

by turbo

I’m having the same problem, but on my lathe. When you say that changing the tolerance to .0001 fixed it do you mean the fusion post options screen? I did that and it didn’t change anything.

Please Log in or Create an account to join the conversation.

26 Mar 2017 17:22 #90304

by turbo

Can I override the error? I just want it to run the code that I feed it.

Please Log in or Create an account to join the conversation.

27 Mar 2017 10:43 #90345

by andypugh

On a lathe it might be a problem with radius/diameter mode or absolute/relative hole centres.

If you over-ride the error, what do you expect LinuxCNC to do? It can’t work out from the input data what the arc radius is.

What is the exact error message, the starting-point of the arc and the G-code line that errors?

Please Log in or Create an account to join the conversation.

27 Mar 2017 14:27 – 27 Mar 2017 15:08 #90373

by Jake

I changed the tolerance in Fusion in the model not in the post processor. It was under preferences I believe, ill look tonight

Make sure your tool offsets are correct also. I have screwed up by having the wrong axis selected when touching off a tool which placed the offset in the wrong axis in the tool table.

Also if your cutter is too large for the radius it will give you that error also.

Last edit: 27 Mar 2017 15:08 by Jake.

Please Log in or Create an account to join the conversation.

27 Mar 2017 23:36 – 27 Mar 2017 23:41 #90405

by turbo

In the tool table am I correct doubling my tool tip radius and putting that in the diameter column? So for my OD profiling tool I have .08 in the diameter column since the tool tip radius is .04mm.

I think I got past this problem yesterday by reducing the tolerance and turning on smoothing in the profiling op. Once I got past that I realized that the g76 format from the tormach post was totally wrong anyway.

Last edit: 27 Mar 2017 23:41 by turbo.

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- CAD CAM

- Radius to end of arc differs from radius to start

Time to create page: 0.234 seconds

Да, вручную работают, Mach3 пишет (Radius to end off arc differs from radius to startLine 50). Через переводчик это (Радиус в конец от дуги отличается от радиус до 50 StartLine). Программы Sheetcam и Mach3 изучил поверхностно, более-менее понятно, но может чего упустил. Например не правильно настроил постпроцессор в Sheetcam или еще чего ? А G-код мой вот:

N0000 (Filename: 11111111111111.tap)

N0010 (Post processor: 5 MP1000-THC-Fan on piercecount.post)

N0020 (Date: 13.11.2013)

N0030 G21 (Units: Metric)

N0040 G53 G90 G40

N0050 F1

N0060 (Part: 11111111111111)

N0070 (Process: Без смещения 0, Фрезер./Гравир., 0,01 mm диаметр, 0 mm Глубина)

N0080 M06 T0 F1 (Фрезер./Гравир., 0,01 mm диаметр)

N0090 G00 Z4.0000

N0100 X182.4162 Y238.9159

N0110 Z0.5000

N0120 G28.1 Z3.00

N0130 G92 Z0.0

N0140 G00 Z0.0600

N0150 G92 Z0.0

N0160 G00 Z0.0000

N0170 M03

N0180 G01 F0

N0190 G03 X167.4162 Y253.9159 I-15.0000 J0.0000 F1.0

N0200 X152.4162 Y238.9159 I0.0000 J-15.0000

N0210 X167.4162 Y223.9159 I15.0000 J0.0000

N0220 X182.4162 Y238.9159 I0.0000 J15.0000

N0230 M05

N0240 G00 Z4.0000

N0250 Y275.4533

N0260 Z0.5000

N0270 G28.1 Z3.00

N0280 G92 Z0.0

N0290 G00 Z0.0600

N0300 G92 Z0.0

N0310 G00 Z0.0000

N0320 M03

N0330 G01 F0

N0340 G03 X167.4162 Y290.4533 I-15.0000 J0.0000 F1.0

N0350 X152.4162 Y275.4533 I0.0000 J-15.0000

N0360 X167.4162 Y260.4533 I15.0000 J0.0000

N0370 X182.4162 Y275.4533 I0.0000 J15.0000

N0380 M05

N0390 G00 Z4.0000

N0400 Y314.1398

N0410 Z0.5000

N0420 G28.1 Z3.00

N0430 G92 Z0.0

N0440 G00 Z0.0600

N0450 G92 Z0.0

N0460 G00 Z0.0000

N0470 M03

N0480 G01 F0

N0490 G03 X167.4162 Y329.1398 I-15.0000 J0.0000 F1.0

N0500 X152.4162 Y314.1398 I0.0000 J-15.0000

N0510 X167.4162 Y299.1398 I15.0000 J0.0000

N0520 X182.4162 Y314.1398 I0.0000 J15.0000

N0530 M05

N0540 G00 Z4.0000

N0550 X147.5063 Y300.7070

N0560 Z0.5000

N0570 G28.1 Z3.00

N0580 G92 Z0.0

N0590 G00 Z0.0600

N0600 G92 Z0.0

N0610 G00 Z0.0000

N0620 M03

N0630 G01 F0

N0640 G03 X119.0287 Y329.1846 I-28.4776 J0.0000 F1.0

N0650 X90.5511 Y300.7070 I0.0000 J-28.4776

N0660 X119.0287 Y272.2294 I28.4776 J0.0000

N0670 X147.5063 Y300.7070 I0.0000 J28.4776

N0680 M05

N0690 G00 Z4.0000

N0700 X182.4162 Y353.3637

N0710 Z0.5000

N0720 G28.1 Z3.00

N0730 G92 Z0.0

N0740 G00 Z0.0600

N0750 G92 Z0.0

N0760 G00 Z0.0000

N0770 M03

N0780 G01 F0

N0790 G03 X167.4162 Y368.3637 I-15.0000 J0.0000 F1.0

N0800 X152.4162 Y353.3637 I0.0000 J-15.0000

N0810 X167.4162 Y338.3637 I15.0000 J0.0000

N0820 X182.4162 Y353.3637 I0.0000 J15.0000

N0830 M05

N0840 G00 Z4.0000

N0850 X0.0000 Y396.7329

N0860 Z0.5000

N0870 G28.1 Z3.00

N0880 G92 Z0.0

N0890 G00 Z0.0600

N0900 G92 Z0.0

N0910 G00 Z0.0000

N0920 M03

N0930 G01 F0

N0940 X200.0000 F1

N0950 Y0.0000

N0960 X138.6285 Y144.9161

N0970 X81.9353

N0980 Y266.9507

N0990 X37.2348

N1000 Y46.7329

N1010 X0.0000

N1020 Y396.7329

N1030 M05

N1040 G00 Z4.0000

N1050 M9

N1060 M05 M30

Как я уже говорил, делал его через Sheetcam. Пробовал через другие программы, все равно не работает.

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Error in Mach 3 – HELP!!!

I’m using Sheetcam to generate my gcode and Mach 3 to cut on the LDR plasma table. I’ve had this error a few times and it seems to be when I’ve chosen “no offset” in the file. I get an error that reads “radius to end of arc differs from radius to start line 234”. I can’t figure out what the issue is. The computer I’m using isn’t connected to the internet, so there hasn’t been any updates that would have screwed anything up. I haven’t changed anything in my config files in the software. I’m at a total loss and need to get some things cut. Any suggestions please?????

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

WyoGreen

- 4 Star Elite Contributing Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Error in Mach 3 – HELP!!!

Post

by WyoGreen » Thu Mar 31, 2016 9:55 pm

I’ve seen this happen before, but I’m not real sure I remember what it was. It seems like it was an error in the G-code post from Sheetcam. I bet if you look at line 234 in the g-code file you’ll see that the command to cut the arc is formatted wrong, or something in that neighborhood.

I’ll keep thinking about it, but that’s the best I have for now.

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

-

KIDTech

- 3 Star Member

- Posts: 359

- Joined: Tue Oct 28, 2014 1:21 pm

Re: Error in Mach 3 – HELP!!!

Post

by KIDTech » Thu Mar 31, 2016 10:34 pm

I get that all the time when I stop a cut mid code. All I do is Rewind (CTRL + W), go back to the last M05, set that line, run from there and hit go. For me this fixes the issue.

DIY 5×10 v rail, rack and pinion

Gecko g540

Pm65 – aka game changer

Longevity ForceCut 42i is sitting on the shelf

Proma THC

ACAD, SheetCam, Mach3

Millermatic 211

NEW HORSE IN THE STABLE:

4’x8′ LDR downdraft w/a scribe

Milltronics Partner 2 CNC mill

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Thu Mar 31, 2016 10:39 pm

WyoGreen wrote:I’ve seen this happen before, but I’m not real sure I remember what it was. It seems like it was an error in the G-code post from Sheetcam. I bet if you look at line 234 in the g-code file you’ll see that the command to cut the arc is formatted wrong, or something in that neighborhood.

I’ll keep thinking about it, but that’s the best I have for now.

Steve

Thanks Steve! I’ve looked at that stinkin’ line and can’t make heads or tails as to what might be wrong. I’m lost!! Thanks for the reply and thanks for thinkin’ about it some more!!

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Thu Mar 31, 2016 10:44 pm

KIDTech wrote:I get that all the time when I stop a cut mid code. All I do is Rewind (CTRL + W), go back to the last M05, set that line, run from there and hit go. For me this fixes the issue.

It won’t even start cutting. It gives me the error as soon as I load the g-code. What’s strange is that in the preview box it doesn’t show anything at all, nothing, nada, zip, zero! It’s very strange. But if I go back to Sheetcam and uncheck the “no offset” operation, leave inside offset and outside offset to cut, resend the g-code and open in Mach 3, it does fine. It obviously has something to do with the no offset, but I’ve never had an issue before.

Any other help is greatly appreciate.

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

acourtjester

- 6 Star Elite Contributing Member

- Posts: 7109

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Error in Mach 3 – HELP!!!

Post

by acourtjester » Thu Mar 31, 2016 10:55 pm

Have you tried to reload SheetCam, Just put your license where you know it is and delete sheetcam and download it again and reinstall and the add your license.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13″ metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Thu Mar 31, 2016 11:14 pm

That was going to be 1st on my list in the morning. This is a very new problem that’s only happened a time or two, but not all the time. Not sure what could have went wrong since this particular computer isn’t connected to the internet to be compromised. Thanks for the tip, I’ll do that in the morning!

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

Old Iron

- 3.5 Star Member

- Posts: 678

- Joined: Wed Nov 26, 2014 5:12 pm

Re: Error in Mach 3 – HELP!!!

Post

by Old Iron » Thu Mar 31, 2016 11:21 pm

Have you updated to the new 6.0.15 version of Sheetcam?

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Thu Mar 31, 2016 11:32 pm

No, I was told when we bought our cutter that we shouldn’t update unless they let us know. I’m guessing I can just Google to find the update?

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

acourtjester

- 6 Star Elite Contributing Member

- Posts: 7109

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Error in Mach 3 – HELP!!!

Post

by acourtjester » Fri Apr 01, 2016 7:52 am

So you understand SheetCam will update itself IF you are connected to the internet when you use it.

What happens when you start SheetCam you will get box message “sheetCam has an update” and you click on OK and it does the update. Maybe 45 seconds and then it starts up the new SheetCam. There dose not seem to be any regular time frame just when they find a bug or a better way to run it.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13″ metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Fri Apr 01, 2016 9:16 am

This computer isn’t connected to the internet. It’s a desktop out in our shop to just run the plasma table. I should be able to put the update on a jump drive and install it though.

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

acourtjester

- 6 Star Elite Contributing Member

- Posts: 7109

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Error in Mach 3 – HELP!!!

Post

by acourtjester » Fri Apr 01, 2016 12:03 pm

Yes sir if the web site has the current last update. Another option is to get a USB wifi stick and plug it into the shop PC for a direct update, if you have wifi near by. one like this

http://www.bestbuy.com/site/tp-link-wir … Id=2080021

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13″ metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Fri Apr 01, 2016 12:40 pm

Thanks I wasn’t even aware there was such a thing? Our shop computer doesn’t even have a modem or wireless card so this should solve that problem. Much appreciated!

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

-

WyoGreen

- 4 Star Elite Contributing Member

- Posts: 897

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Error in Mach 3 – HELP!!!

Post

by WyoGreen » Fri Apr 01, 2016 2:09 pm

I’m using Sheetcam to generate my gcode and Mach 3 to cut on the LDR plasma table. I’ve had this error a few times and it seems to be when I’ve chosen “no offset” in the file. I get an error that reads “radius to end of arc differs from radius to start line 234”. I can’t figure out what the issue is. The computer I’m using isn’t connected to the internet, so there hasn’t been any updates that would have screwed anything up. I haven’t changed anything in my config files in the software. I’m at a total loss and need to get some things cut. Any suggestions please?????

If you can take a screenshot of the offending line and the lines before and after it, we can probably figure out what’s going wrong.

Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

-

dhelfter

- 2.5 Star Member

- Posts: 125

- Joined: Wed Sep 09, 2009 11:18 pm

Re: Error in Mach 3 – HELP!!!

Post

by dhelfter » Sat Apr 02, 2016 9:37 pm

This problem was do to having an over cut on the open entities.

Dan

Ldr

-

oldmountaincrafts

- 2 Star Member

- Posts: 88

- Joined: Sat Oct 12, 2013 7:46 pm

Re: Error in Mach 3 – HELP!!!

Post

by oldmountaincrafts » Sat Apr 02, 2016 9:58 pm

Thanks Dan!!! Hadn’t had a chance to get back on here and update the post. I then ran into another issue that I emailed you about. I found a work around by your great videos on your website, but I still have to fix the problem. It was acting all around weird. I did the troubleshooting videos for communication issues, torch not cutting and not firing. I ended up having to go to manual and torch height (?) off and then everything cut great. I still can’t get the power light on my HUB to come on though. Thanks for being so great!

LDR Motionsystems 4×4 plasma

Hypertherm 45

Laser 4 X 4

Full woodshop

Return to “Mach3 & Mach4 CNC”

Jump to

- WELCOME CENTER, GOOD INFO & MEET OUR SPONSORS

- ↳ Introduce Yourself

- ↳ CNC Plasma Beginners Knowledge Base

- ↳ Contributing Membership Registration or Renewal

- ↳ PlasmaSpider Online Store

- ↳ Our Sponsors & Advertisers

- DXF DESIGN & PROJECT PICTURE SHARING FORUMS

- ↳ DXF Art – DXF Clip Art File Sharing Forum

- ↳ CNC Plasma Cutter Project Picture Gallery

- ↳ File Conversion Help Wanted

- GENERAL FORUMS

- ↳ CNC Plasma Cutters General Forum

- ↳ Plasma Cut Quality Forum

- ↳ Hypertherm’s Basic Tips to Improve Cut Quality

- ↳ Hypertherm’s 10 Common Plasma Cutting Mistakes

- ↳ Hypertherm’s Tips to Troubleshoot Cut Angularity

- ↳ Pricing, Advertising, & Marketing Your Products Forum

- ↳ Tech Tips From Other Members

- ↳ Classified Ads

- PLASMA CUTTER FORUMS

- ↳ Hypertherm Plasma Cutters

- ↳ Powermax Helpful Resources

- ↳ Powermax Cut Speed Charts

- ↳ Powermax Cut Speed Charts

- ↳ Powermax SYNC 65, 85, 105 Cut Speed Charts

- ↳ Powermax 45 Cut Speed Charts

- ↳ Powermax 65/85 Cut Speed Charts

- ↳ Powermax 105 Cut Speed Charts

- ↳ Powermax 125 Cut Speed Charts

- ↳ Powermax Fault Code, Diagnostics, & Troubleshooting Forums

- ↳ Powermax 65 & 85 Common Fault Code, Diagnotics, & Troubleshooting Forum

- ↳ 0-12 Fault Code

- ↳ 0-19 Fault Code

- ↳ 0-20 Fault Code

- ↳ 0-21 Fault Code

- ↳ 0-22 Fault Code

- ↳ 0-30 Fault Code

- ↳ 0-99 fault Code

- ↳ Displaying the Powermax 65 85 Service Screen

- ↳ Thermal Dynamics / Esab Plasma Cutters

- ↳ Cutmaster A40 Cut Speed Charts

- ↳ Cutmaster A60 Cut Speed Charts

- ↳ Cutmaster A80 Cut Speed Charts

- ↳ Cutmaster A120 Cut Speed Charts

- ↳ Lincoln & Miller Plasma Cutters

- ↳ RazorWeld, Everlast, & All Other Plasma Cutters

- ↳ Plasma Consumables

- CNC PLASMA TABLE & CONTROLLER FORUMS

- ↳ CandCNC Forum

- ↳ CandCNC Website

- ↳ FastCut CNC Forum

- ↳ FlashCut CNC Forum

- ↳ JD Squared Forum

- ↳ JD Squared Website

- ↳ MultiCam Forum

- ↳ Shop Sabre Forum

- ↳ Star-Lab CNC Forum

- ↳ Tracker CNC Forum

- ↳ Langmuir Crossfire Forum

- ↳ PlasmaCam, Samson, & Go Torch Forum

- ↳ Torchmate Forum

- ↳ DIY Plasma Table & Accessory Discussion Forum

- ↳ Various Manufacturers Forum

- CAD-CAM & CONTROL SOFTWARE FORUMS

- ↳ General Discussion

- ↳ Fusion 360 & AutoCAD Forum

- ↳ Get AutoDesk Fusion 360 FREE

- ↳ BobCAD

- ↳ C&CNC CommandCNC

- ↳ Corel Draw Graphics Suite

- ↳ CorelDRAW Free 30 day trial

- ↳ Quick & Helpful CorelDRAW Tutorial Videos

- ↳ Inkscape

- ↳ Download Inkscape for Windows

- ↳ Linux CNC – Plasmac

- ↳ Mach3 & Mach4 CNC

- ↳ Plasmacam – DesignEdge

- ↳ SheetCam

- ↳ Torchmate Software

- METAL FINISHING FORUMS

- ↳ Patina Finishes

- ↳ Steel F/X Your Metal Patina & Dye Connection

- ↳ Paint & Other Top Coats

- ↳ Powder Coat

- ↳ Abrasive & Texturing

- ↳ Dross/Slag Removal

- ACCESSORIES & RELATED TOOL FORUMS

- ↳ EasyScriber Drag Style Scriber for Hypertherm

- ↳ EasyScriber for Hypertherm, Thermal Dynamics, Razorweld, Esab

- ↳ Plate Markers, & Air Scribes

- ↳ Mig Welders, Tig Welders, Spot Welders

- ↳ Metal Bending, Rolling, Notching, Drilling, Saw Cutting

- ↳ Air Dryers, Air Filters, Air Compressors, Etc.

- ↳ Water Tables, Ventilation, Air Handling

- ↳ Fab Tables, Grind Stations, Material Storage & Handling

- ↳ Pen Markers, Remote Controls, Drawing Tablets, etc.

- ↳ 3D Printers & Printed Accessories

- ↳ Laser Engravers & Cutters

- ↳ Arclight Dynamics